|

|

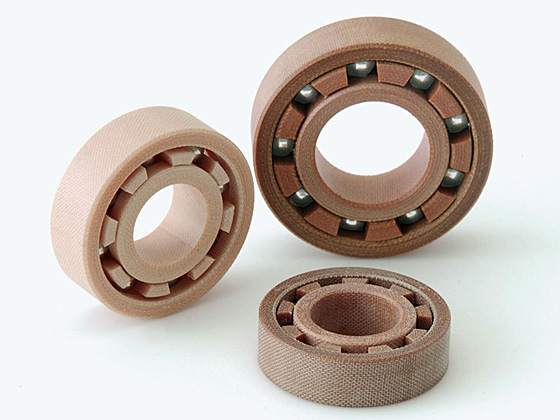

Phenolic resin is a material with very special features and is therefore very popular for use in plastic bearings.

Overview of Phenol

Phenolic resin (e.g., Bakelite, formaldehyde resin, carbolic acid resin)

Phenolic resin is a thermosetting resin made from phenol and formaldehyde, and it is the world’s first plastic synthesized from non-vegetable raw materials. Similar resins can also be produced from phenols such as cresol, so these resins are often referred to as phenolic resins. It boasts excellent insulation and non-magnetic properties, high resistance to oil and chemicals, and strong heat resistance, but it is weak against alkaline substances. Considering its performance, it can be considered relatively inexpensive.

Characteristics of Phenol

◎Recommended ○Satisfactory △Possible to use, but not recommended ×Not compatible

| Material | Product code |

Dry | Water (extended periods of time) |

Water |

Steam | Chemical environment | Magnetic environment | As insulator | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Acids | Alkaline | Organic liquids | Oil | ||||||||

| Phenol | SD | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | ◎ | ◎ |

| SDK | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | × | × | |

| SDHG | ◎ | △ | △ | × | ○ | × | ○ | ◎ | × | × | |

| PTFE | PT | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × |

| PTG | ◎ | ◎ | ◎ | ◎ | ◎ | × | ◎ | ◎ | ◎ | ◎ | |

| PTE | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| PTN | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| UHMW | PE | ○ | ○ | ◎ | × | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PP | PP | △ | ○ | ○ | △ | ○ | ○ | ○ | ○ | ◎ | ◎ |

| PEEK | PK | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PKG | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PPS | PS | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PSG | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PCTFE | PCT | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| PVDF | PV | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| Carbon | CY | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ○ | × |

Note: Please contact us for detailed information regarding compatibility with specific chemicals.

Temperature resistance performance of Phenol

☆Highly recommended ◎Recommended ○Satisfactory △Possible to use, but not recommended ×Not compatible

| Material | Product code |

Temperature | |||||||

| -190℃~ | -100℃~ | -50℃~ | -20℃~ | Room or operating temperature | ~120℃ | ~200℃ | ~350℃ | ||

| Phenol | SD | × | × | 〇 | ◎ | ☆ | ◎ | × | × |

| SDK | × | × | 〇 | ◎ | ☆ | ◎ | × | × | |

| PTFE | PT | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × |

| PTG | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × | |

| PTE | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × | |

| UHMW | PE | × | △ | 〇 | 〇 | ☆ | × | × | × |

| PP | PP | × | △ | 〇 | 〇 | ☆ | 〇 | × | × |

| PEEK | PK | × | × | 〇 | ◎ | ☆ | ◎ | 〇 | × |

| PKG | × | × | 〇 | ◎ | ☆ | ◎ | ◎ | × | |

| PPS | PS | × | × | × | 〇 | ☆ | ◎ | 〇 | × |

| PSG | × | × | × | 〇 | ☆ | ◎ | 〇 | × | |

| PCTFE | PCT | × | × | 〇 | ◎ | ☆ | 〇 | × | × |

| Carbon | CY | × | × | △ | 〇 | ☆ | ◎ | ◎ | ◎* |

*Note: Please consider the coefficient of thermal expansion, or contact us for specialized applications.