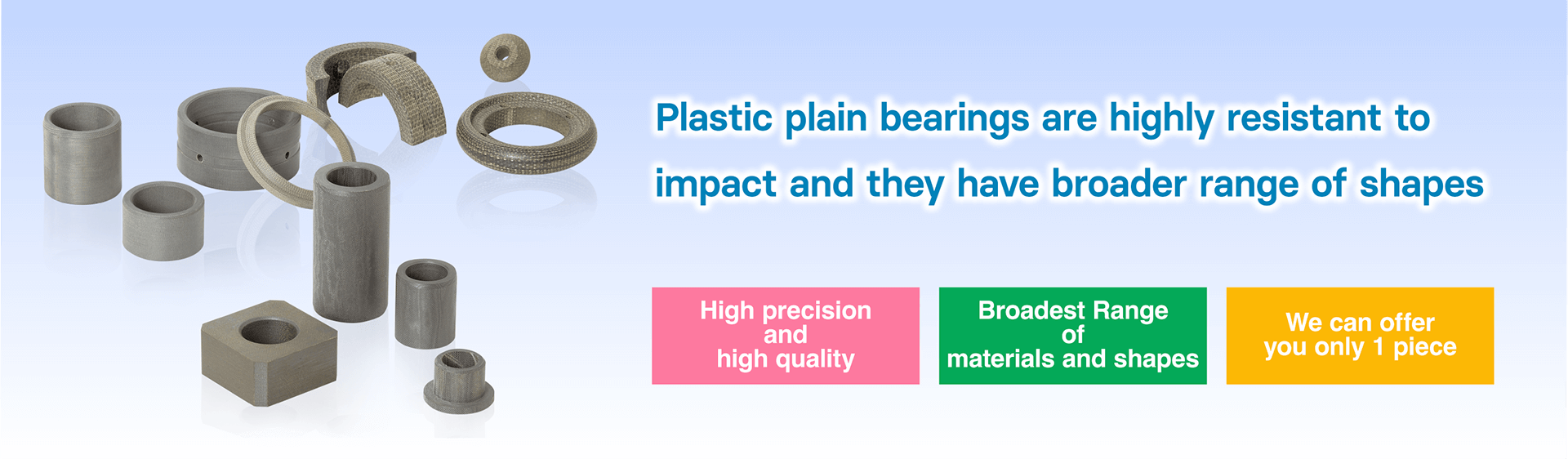

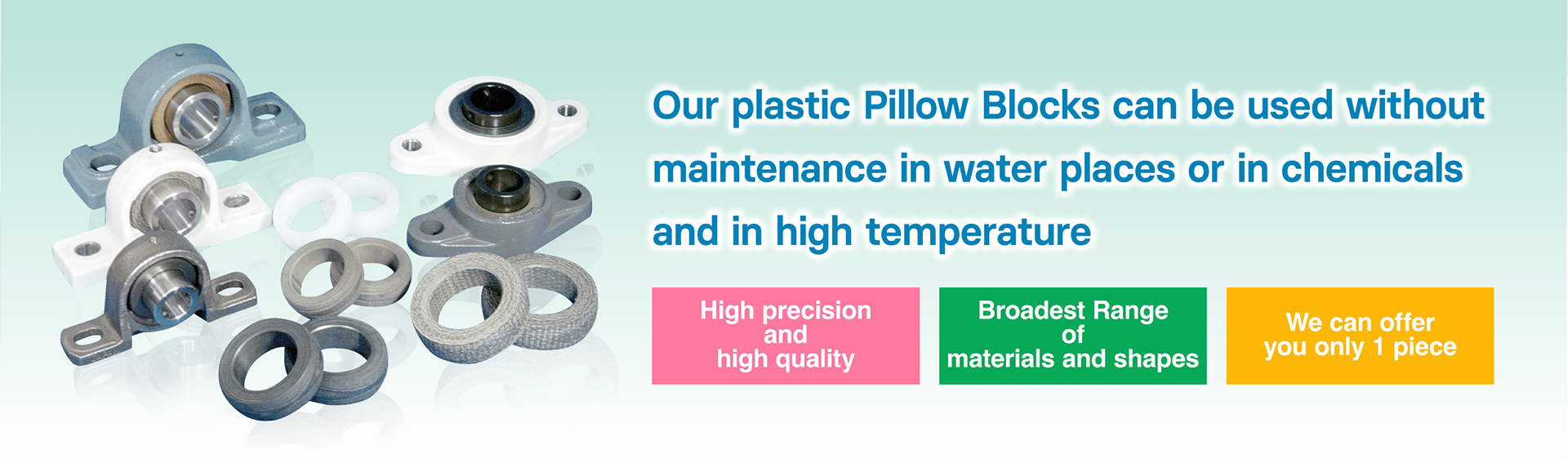

Why do we hold a 40% market share in Japan? There are numerous reasons why our customers choose us, but what truly positions Kashima Bearings, Inc. as a leading manufacturer is our deep understanding of plastics and resins. We customize our plastic and resin bearings to seamlessly meet the diverse needs of various factory environments. These bearings offer advantages that metal bearings lack.

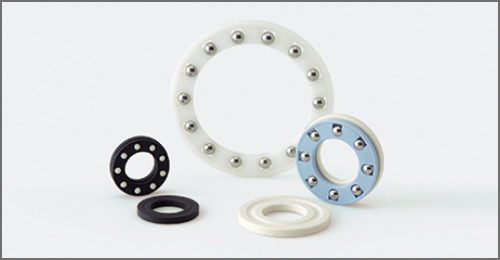

Plastic Ball Bearings

We will offer you the most suitable product for your usage conditions.

Please don't hesitate to contact us if you have any questions.