Deep groove bearings (single-row deep groove ball bearings) represent the most typical form of ball bearings (rolling bearings) and are extensively utilized. They comprise raceway rings (inner and outer rings), balls, and a cage that supports the balls.

Primarily designed to withstand radial loads (perpendicular to the axis), they can also support axial loads in both directions.

Featuring a low coefficient of friction, they are suitable for applications requiring stable rotation.

The groove of the raceway ring forms a circular arc slightly larger than the radius of the ball, resulting in point contact between the ball and raceway ring. This design, compared to plain bearings, reduces resistance to rotation, making them ideal for applications requiring stable rotation.

Structure of the Bearings:

We primarily utilize plastic as a bearing material. Plastic bearings offer various advantages distinct from metal bearings, including the ability to function without lubrication or oiling, and resistance to rust or corrosion when exposed to water or chemicals.

Features of the Bearings:

Plastic bearings find application in special environments where metal bearings are unsuitable. However, no single plastic material is universally suitable for all special environments. Hence, we recommend different materials based on the intended environment of use. Additionally, since we manufacture by cutting, we can produce bearings in any desired shape.

If you encounter any issues with bearings or related matters, we are available to visit you for assistance. Please feel free to contact us.

Major Sizes

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

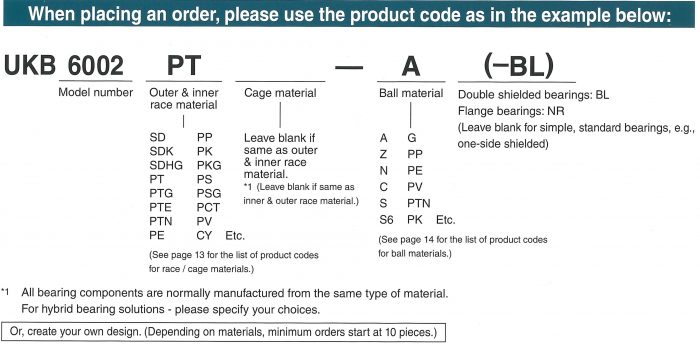

Choose the best outer inner rings and a cage material

Choose the best ball materials

|

The material selection for plastic bearings depends on the intended use of the bearing. |

|

Plastic bearings, including polymer bearings, find application in a wide variety of scenarios owing to their superior characteristics, which are not typically found in metal bearings. They serve diverse purposes across various applications. |

Back to Product Line