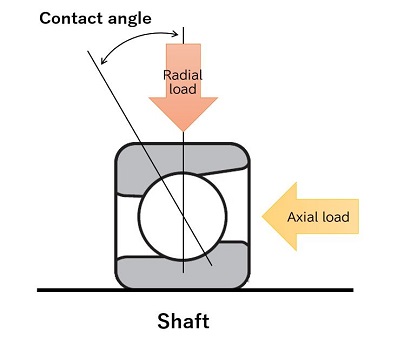

Angular-contact ball bearings are capable of handling both radial loads and thrust loads in one direction.

There exist various types of ball bearings, each tailored for specific environments and load conditions. For instance, the focus here is on load-bearing characteristics, outlined below:

| Deep-groove Ball Bearings: | A versatile type of bearing capable of supporting axial loads parallel to the shaft (axial loads) and radial loads perpendicular to the shaft. |

| Thrust Ball Bearings: | Designed to withstand thrust loads in one direction. |

| Angular-contact Ball Bearings | Able to accommodate both radial and thrust loads in one direction. |

While angular-contact bearings closely resemble deep groove bearings, their performance differs due to a distinctive feature in the raceway ring.

A deep-groove bearing consists of an inner ring serving as a raceway, an outer ring, a cage, and balls. Angular-contact bearings share the same components. However, while the grooves of a deep groove bearing are symmetrical when viewed from the center, angular-contact bearings have grooves set at a specific angle, enabling force transmission from one groove to another diagonally. This angle is termed the contact angle. A larger contact angle allows for higher thrust loads but results in a lower allowable speed. Standard contact angles typically include 15, 30, and 40 degrees. Some manufacturers may adopt a 25-degree contact angle or other custom angles.

There are several types of angular bearings available:

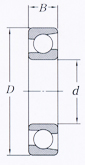

- Single-row angular bearings: Similar in appearance to deep groove bearings.

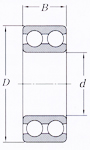

- Double-row angular bearings: Structure in which single-row angular bearings are combined to form a single inner and outer ring.

| Single-row Angular Ball Bearings | Double-row Angular Ball Bearings |

Single-row angular bearings have a structure resembling deep groove bearings. |

Double-row angular bearings integrate inner and outer rings by combining single-row angular contact bearings. |

Combination angular bearings involve combining two single-row angular bearings. As this combination yields different characteristics, it can be adjusted to suit specific environments.

However, it’s important to note that single-row angular contact bearings may not be suitable for applications where loads are applied from both radial and axial directions. The choice between deep groove bearings and single-row angular contact bearings depends on operational conditions.

As mentioned earlier, while deep groove bearings can handle both radial and thrust loads, they are not suitable for high thrust loads. On the other hand, angular contact bearings, with their contact angle, can endure larger thrust loads than deep groove bearings but only in a single direction. Bearing selection should be made with careful consideration of the operating environment.

At our company, we manufacture angular contact bearings as well. One noteworthy feature of our angular contact bearings is their cost-effectiveness compared to single-row angular contact bearings. This is because a single double-row angular bearing is less expensive than two single-row angular bearings.

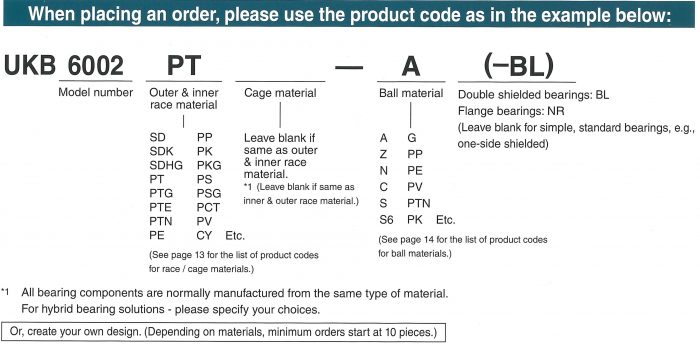

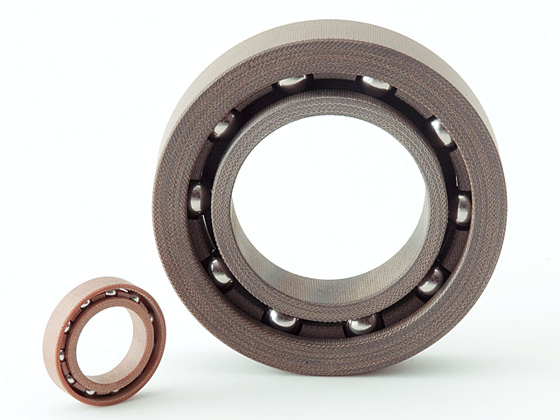

Since we manufacture bearings from a single piece by cutting, we can easily produce special shapes such as double-row bearings without any difficulty. Additionally, our bearings are made of resin and are suitable for various special environments where metal bearings are unsuitable.

Our resin bearings excel in the following specialized environments:

- Underwater: They can be used without concern for rusting.

- Chemical environments: They are resistant to corrosion.

- High-temperature environments: Heat-resistant resin variants are available, eliminating concerns about grease drying up.

- Non-magnetic environments: They can be utilized in metal detectors, etc., as they are non-magnetic.

- Environments requiring insulation: They can be employed in locations where the passage of electricity is undesired.

We provide assistance in material selection and offer the flexibility to manufacture small lots of 10 pieces. If you have any inquiries about bearings or plastics in specialized environments, please don’t hesitate to contact us for a consultation.

Major Sizes

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The material selection for plastic bearings depends on the intended use of the bearing. |

|

Plastic bearings, including polymer bearings, find application in a wide variety of scenarios owing to their superior characteristics, which are not typically found in metal bearings. They serve diverse purposes across various applications. |

Back to Product Line