|

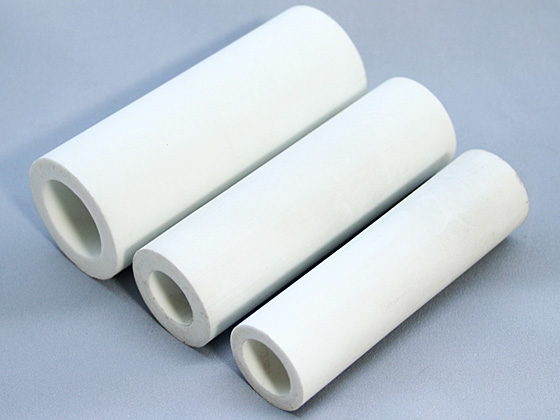

PTFE (Polytetrafluoroethylene) is a material with very special characteristics and is therefore very popular for use in plastic bearings. |

|

|

|

|

Overview of PTFE

PTFE is a type of Teflon, known as Teflon R (Polytetrafluoroethylene).

The term “TEFLON” is a registered trademark of DuPont. Originally, the material was called “Tetra Fluor Ethylene Resin,” or sometimes “Poly Tetra Fluor Ethylene” (e.g., PTFE).

As it is a very popular material, it is one of our most familiar materials in terms of its nature and properties.

This plastic was developed in 1938 by Dr. Plunkett of DuPont and registered with the “TEFLON” trademark in 1944. Today, it is a commonplace material found in every household.

Characteristics of PTFE

- Temperature resistant from -196 ℃ to +260 ℃

- Excellent insulator

- Highly resistant to acids and alkalis as well as very stable against organic solvents

- No water absorption of the material

- Friction properties are lower than the lowest coefficient on ice

- Bonding properties: it is highly unlikely that other materials will bond

It possesses such properties, but at the same time, it exhibits high thermal expansion and sensitive dimensional changes, which make it soft.

When PTFE is used as a mechanical component, the mentioned dimensional changes and softness can be hindering.

To improve these points, PTFE is sometimes filled with fillers. An important purpose of the fillers is to increase wear resistance. Materials such as carbon and glass are used as fillers.

In our company, we utilize

- the chemical resistance of PTFE to use it in areas where aggressive chemicals such as sulfuric acid, hydrochloric acid, ammonia, and hydrofluoric acid are used.

- Furthermore, its non-stick properties are utilized to use it in food processing lines where the adherence of dirt during cleaning is undesirable.

We offer products tailored to the needs of our customers by utilizing the properties of PTFE.

◎Recommended ○Satisfactory △Possible to use, but not recommended ×Not compatible

| Material | Product Code |

Dry | Water (extended periods of time) |

Water |

Steam | Chemical Environment | Magnetic Environment |

As Insulator |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Acids | Alkaline | Organic Liquids |

Oil | ||||||||

| Phenol | SD | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | ◎ | ◎ |

| SDK | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | × | × | |

| SDHG | ◎ | △ | △ | × | ○ | × | ○ | ◎ | × | × | |

| PTFE | PT | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × |

| PTG | ◎ | ◎ | ◎ | ◎ | ◎ | × | ◎ | ◎ | ◎ | ◎ | |

| PTE | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| PTN | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| UHMW | PE | ○ | ○ | ◎ | × | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PP | PP | △ | ○ | ○ | △ | ○ | ○ | ○ | ○ | ◎ | ◎ |

| PEEK | PK | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PKG | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PPS | PS | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PSG | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PCTFE | PCT | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| PVDF | PV | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| Carbon | CY | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ○ | × |

Note: Please contact us for detailed information regarding compatibility with specific chemicals.

Temperature resistance performance of PTFE

☆Highly recommended ◎Recommended ○Satisfactory △Possible to use, but not recommended ×Not compatible

| Material | Product Code |

Temperature | |||||||

| -190℃~ | -100℃~ | -50℃~ | -20℃~ | Room or Operating Temperature | ~120℃ | ~200℃ | ~350℃ | ||

| Phenol | SD | × | × | 〇 | ◎ | ☆ | ◎ | × | × |

| SDK | × | × | 〇 | ◎ | ☆ | ◎ | × | × | |

| PTFE | PT | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × |

| PTG | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × | |

| PTE | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × | |

| UHMW | PE | × | △ | 〇 | 〇 | ☆ | × | × | × |

| PP | PP | × | △ | 〇 | 〇 | ☆ | 〇 | × | × |

| PEEK | PK | × | × | 〇 | ◎ | ☆ | ◎ | 〇 | × |

| PKG | × | × | 〇 | ◎ | ☆ | ◎ | ◎ | × | |

| PPS | PS | × | × | × | 〇 | ☆ | ◎ | 〇 | × |

| PSG | × | × | × | 〇 | ☆ | ◎ | 〇 | × | |

| PCTFE | PCT | × | × | 〇 | ◎ | ☆ | 〇 | × | × |

| Carbon | CY | × | × | △ | 〇 | ☆ | ◎ | ◎ | ◎* |

*Note: Please consider the coefficient of thermal expansion, or contact us for specialized applications.