As the name suggests, a thrust bearing is designed to withstand thrust loads.

Thrust loads, also known as axial loads, are forces applied in the same direction as the shaft. Due to the even distribution of this load, thrust bearings exhibit the highest level of stability among plastic bearings.

They can be employed in specialized environments where exposure to water or chemicals is common, without succumbing to rust or corrosion. Moreover, unlike metal bearings that rely on grease for lubrication, plastic bearings can operate without lubrication, thus requiring minimal maintenance.

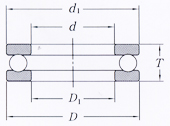

Only the ball retainer component is available for manufacture and use. While the main dimensions are provided below, we can also accommodate other dimensions upon request.

Orders can be placed with a minimum quantity of 10 pieces.

For inquiries regarding applications in unique environments, please don’t hesitate to contact us.

Major Sizes

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

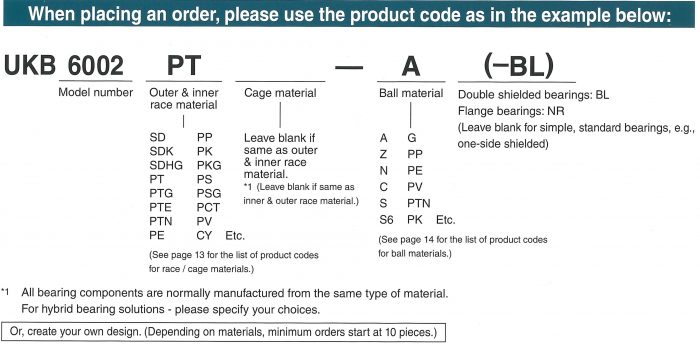

Choose the best outer inner rings and a cage material

Choose the best ball materials

|

The material selection for plastic bearings depends on the intended use of the bearing. |

|

Plastic bearings, including polymer bearings, find application in a wide variety of scenarios owing to their superior characteristics, which are not typically found in metal bearings. They serve diverse purposes across various applications. |

Back to Product Line