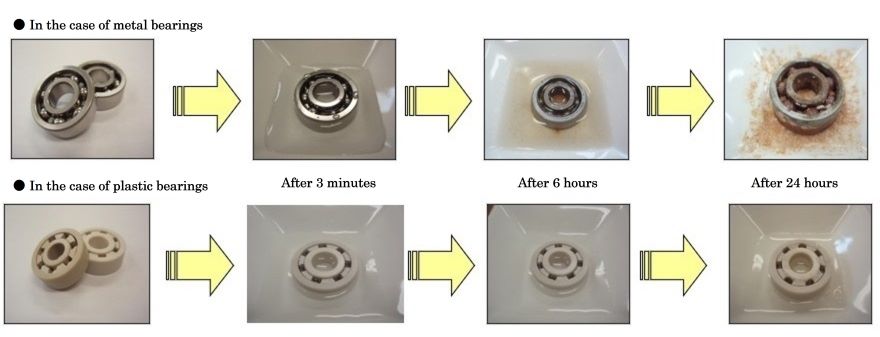

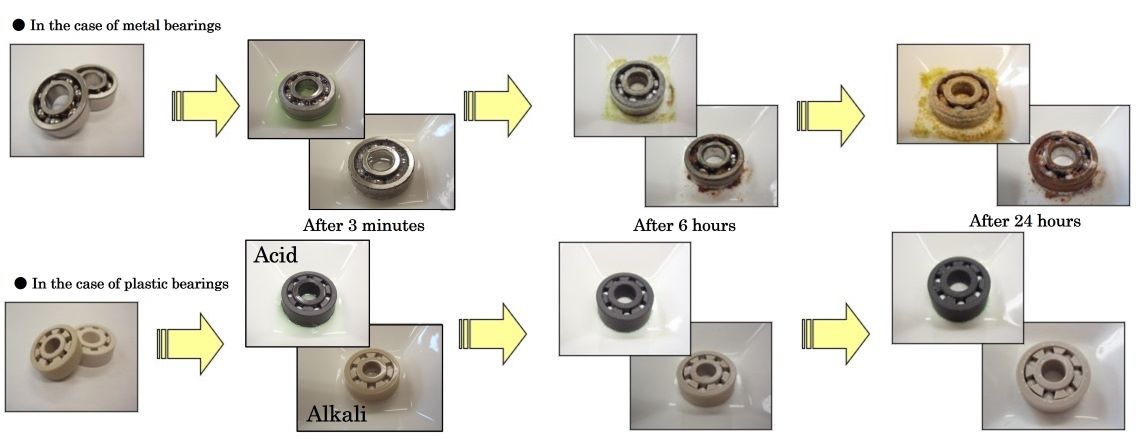

The photos below show the changes observed when metal bearings and plastic bearings were immersed in salt water or chemicals. Each bearing was placed in the liquid for 3 minutes, 6 hours, and 24 hours, and the results were compared.

For the plastic bearings, we used materials suited to each liquid: salt water, acid, and alkali.

1. Salt Water

2. Chemicals (Acid & Alkali)

In both cases, there was little change after just a few minutes. However, over time, the metal bearings began to show signs of rust, and after 24 hours they were completely corroded and unusable.

In contrast, the plastic bearings showed no change after 24 hours. Even after continuing the test for another 24 hours — a total of 48 hours — no changes were observed.

Below is a comparison after 24 hours.

(The deposits seen on the plastic bearings are crystals left behind after the liquid evaporated.)

● Metal Bearings

Salt Water |

Acidic Cleaning Agent |

Alkaline Cleaning Agent |

● Plastic Bearings

Salt Water |

Acidic Cleaning Agent |

Alkaline Cleaning Agent |

Even if you already understand the difference in corrosion resistance, seeing it visually after just 24 hours has a much greater impact.

As shown, in environments such as underwater or in chemical solutions — where metal bearings cannot be used — plastic bearings remain free from corrosion and can be used for a long service life.

If you can provide details about your operating environment and the chemicals involved, we can recommend the most suitable material.

Click here to contact us