Plastics and Electrical Insulation

One notable characteristic of plastics is their insulating property.

Insulation means being resistant to the flow of electricity, and “insulating property” refers to the degree to which a material resists electrical current. Plastics, rubber, glass, and other such materials with this property are called insulators.

|

|

|

As mentioned, plastics are generally insulating materials.

From general-purpose plastics such as polyethylene, polypropylene, and PVC, to engineering plastics like nylon and POM, and super engineering plastics like PEEK, PPS, and PTFE (Teflon), as well as thermosetting resins such as phenolic and epoxy — all have insulating properties.

UHMW UHMW |

PEEK PEEK |

Phenolic Resin Phenolic Resin |

Applications of Insulating Plastic Bearings

Our bearings are also used for their insulating properties.

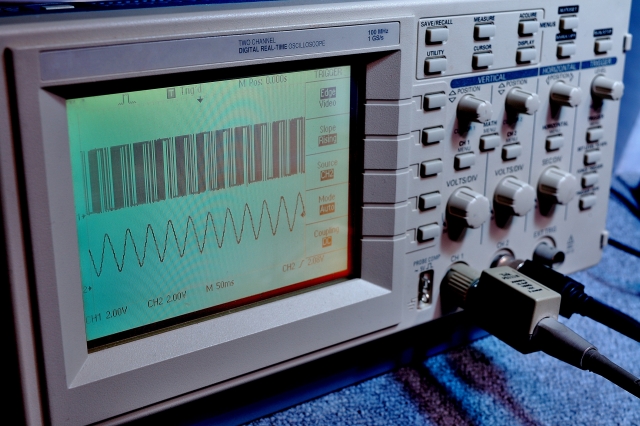

For example, in inspection and measurement equipment, plastic bearings can be used to prevent frequency disturbances caused by electrical current, ensuring stable measurements. They are also used near metal detectors to prevent false signals. In the medical field, they may be used to prevent malfunction of electrosurgical devices. There are many environments where insulation is essential.

|

|

|

Static Electricity in Plastics

On the other hand, plastics also tend to become electrostatically charged.

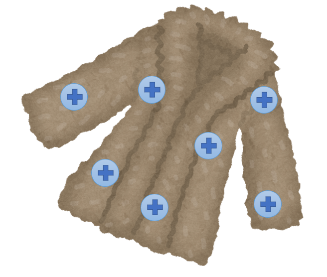

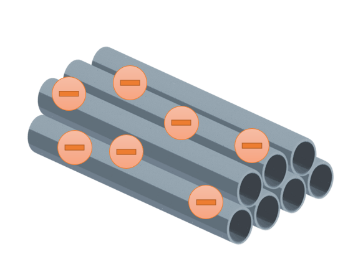

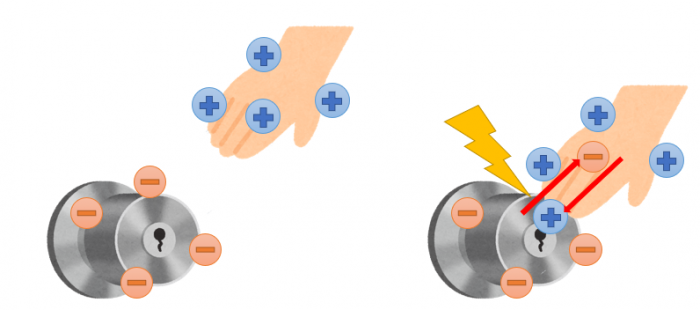

This is true of all materials — static electricity is generated when two materials rub against each other. While the detailed explanation involves atomic theory, in simple terms, all substances carry positive (+) and negative (−) “charges.” When materials come into contact, these charges can move from one to the other. Some materials attract positive charges, others negative (plastics tend to attract negative charges). When one type of charge accumulates on the surface and remains, the material is “charged,” and because the charges stay in place, we call it “static” electricity. Charging = Static Electricity.

|

|

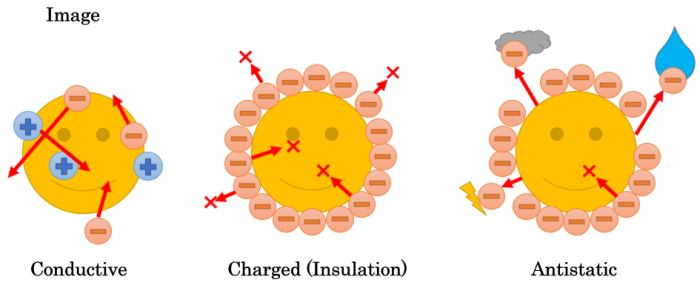

To neutralize this, materials try to balance positive and negative charges. For example, when a positively charged object approaches a negatively charged one, excess positive charges will transfer to combine with the negative charges. The instant this happens, current flows — this is static discharge (the small “zap” you feel). Conductors can transfer charges easily to eliminate static, but insulators like plastics cannot, so the charged state persists.

In some products and equipment, static electricity itself can cause problems — damaging components, generating noise, attracting dust, or even causing accidents or fires. In industrial production, these are well-known issues. The two main solutions are conductivity and antistatic treatment. Even plastics, which are naturally insulating, can be adapted to have these properties.

Conductive Plastics

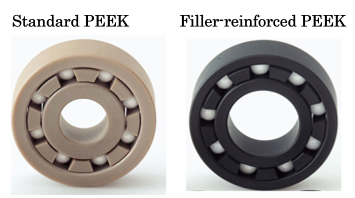

Conductivity can be imparted by mixing conductive particles, such as carbon, into the resin before molding. This creates a hybrid material combining the properties of both the resin and the filler. At Kashima Bearings, we offer carbon graphite-filled materials as a conductive grade. Conductive plastic bearings are used when lubrication is undesirable but conductivity is required. Depending on the resin, they can also be used in water or chemical environments. Carbon-filled grades are generally black in appearance.

Antistatic Plastics

However, adding conductive fillers like carbon eliminates the original insulating properties of plastic. The other option is antistatic treatment.

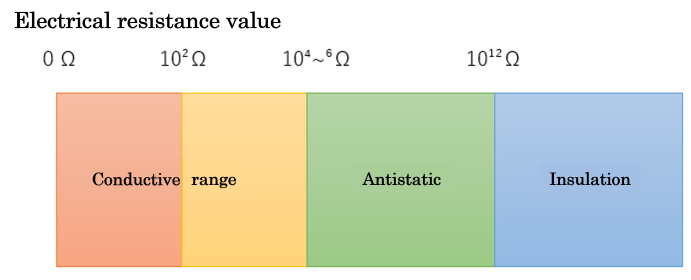

In plastics, antistatic treatment means giving the resin surface slight conductivity to help dissipate static and prevent it from building up. This allows static to discharge into the surrounding air, typically via moisture. The key factor here is electrical resistance — insulation, conductivity, and antistatic properties are all defined by it.

The higher the resistance, the more electricity accumulates and the harder it is for current to flow; the lower the resistance, the easier the flow. Antistatic materials have a resistance lower than insulating materials but high enough to avoid being conductive. This enables the surface to release static into the air without the material itself conducting electricity.

At Kashima Bearings, we use antistatic-grade materials to manufacture and supply antistatic bearings, and we have delivered them to various customers.

In summary, plastics have distinct electrical properties — insulation, antistatic, and conductivity — each with different uses and characteristics. We can propose plastic products tailored to your application environment. Please feel free to consult with us about any requirements or challenges.