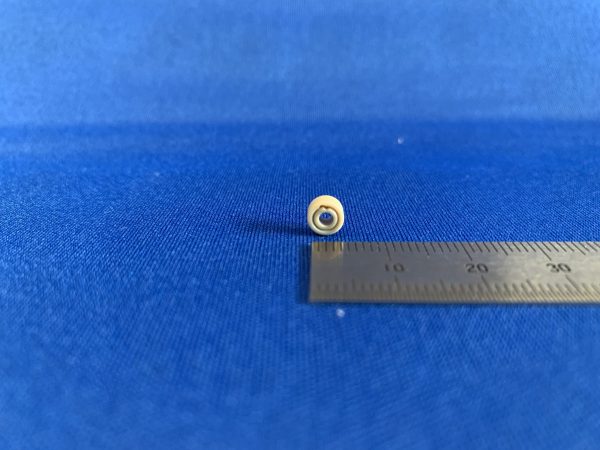

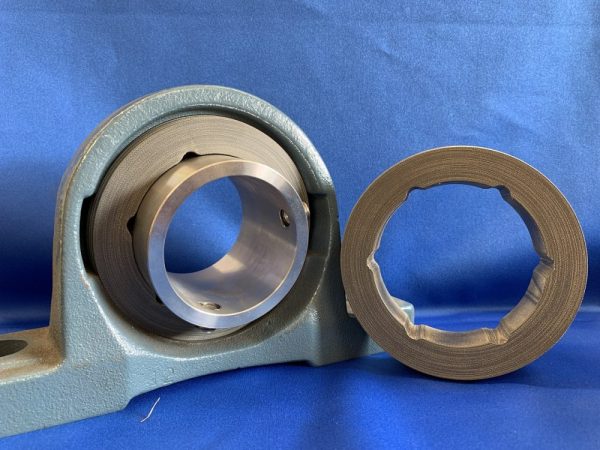

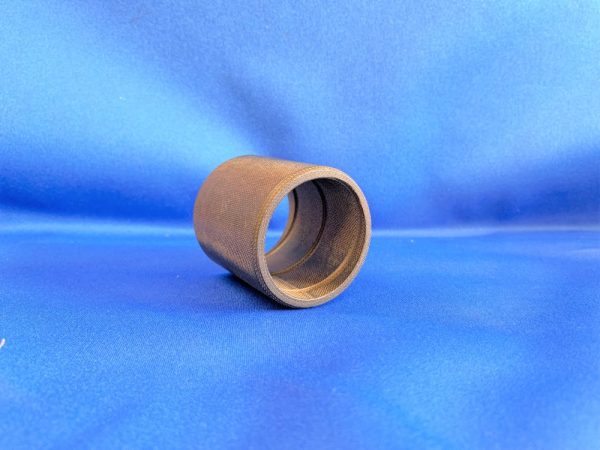

Double-Row Full-Ball Plastic Bearing (Contamination Countermeasure)

Below is an introduction to a bearing that has been adopted for use in a conveyor system. This product was considered for use in equipment where sterilization is performed using high-temperature cleaning showers or chemical agents. In such harsh environments, components contained in tap water—such as calcium, magnesium, and silica—tend to crystallize as the water dries and easily adhere to the bearing surfaces. To facilitate the cleaning and removal of these crystallized contaminants, we proposed a full-ball design without a cage. This structure allows foreign matter to be more easily flushed out during cleaning. However, because the balls in a full-ball design are in direct contact with one another, its[…..]