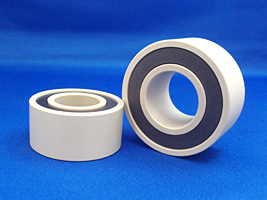

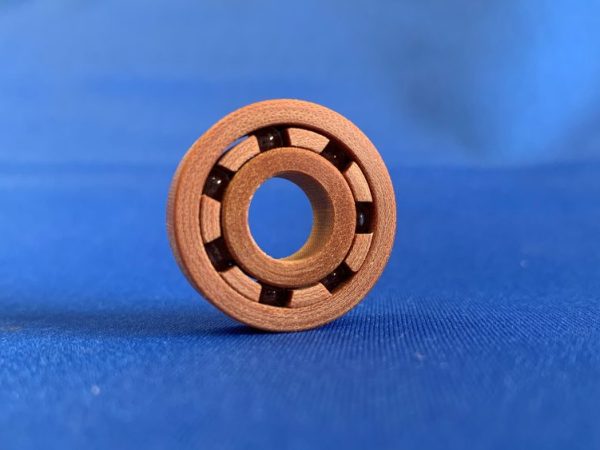

Plastic Bearings for Transporting Hoop Materials (Coil Materials)

This product is a specially shaped bearing with a flat groove on the outer diameter and an extended inner ring on one side. The groove shape can be custom-made to match the transported material. Can be used without collars when multiple bearings are installed in parallel. Excellent chemical resistance allows usage even in highly corrosive chemical solutions. The outer diameter section features a flat groove, enabling a custom-made design tailored to the size of thin metal sheets (hoop materials). This flat groove ensures precise guidance of the transported material, preventing scratches and damage. In addition to thin metal sheets (hoop materials), various groove shapes such as V-grooves and R-grooves can[…..]