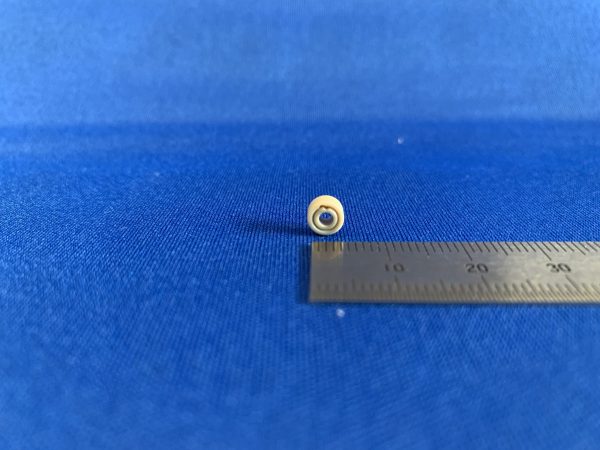

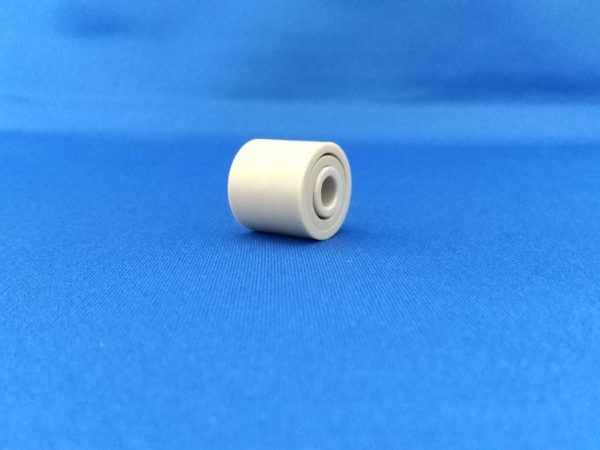

Small-Diameter Plastic Ball Bearings (φ5 / Miniature)

The photo shows an ultra-miniature bearing with dimensions of φ5×φ2×3L which was considered for use in a certain medical device project. When we initially discussed the project, we explained that due to the extremely small diameter, it would be difficult to determine whether production was feasible without first attempting it. However, after prototyping in-house, we found that it was indeed possible to manufacture. Due to the lack of space to insert a retainer, the design uses a full ball configuration. In medical equipment, not only are cleaning and sterilization essential, but there is also the possibility of blood exposure, which can lead to corrosion — making the use of metal[…..]