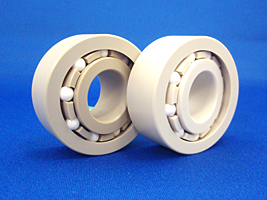

High-Load Plastic Roller Bearings for Solar Cells

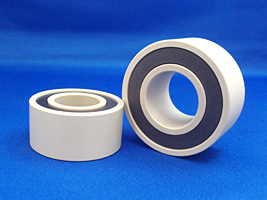

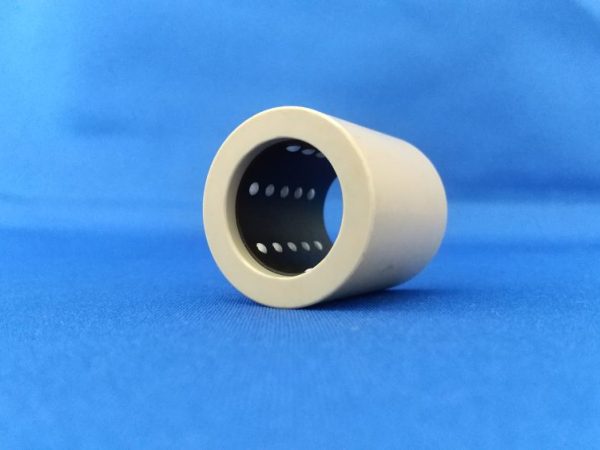

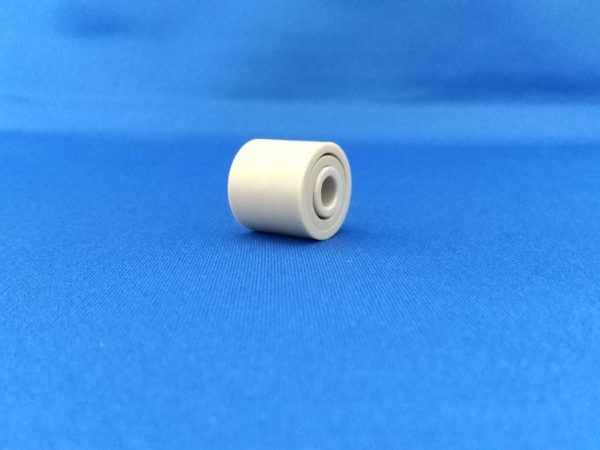

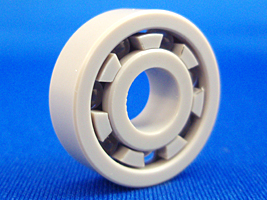

Conventional plastic deep groove ball bearings use balls that rotate at a point, whereas plastic roller bearings use rollers that rotate along a line, allowing them to withstand greater loads. Currently, they are used in applications such as conveyor rollers for transporting materials in chemically-laden environments within solar cell production facilities. Plastic Roller Bearings This is how the roller looks like. Related Pages ・Custom-made Ball Bearings ・Chemical Environment ・Wells & Environmental Pumps Back to Case studies