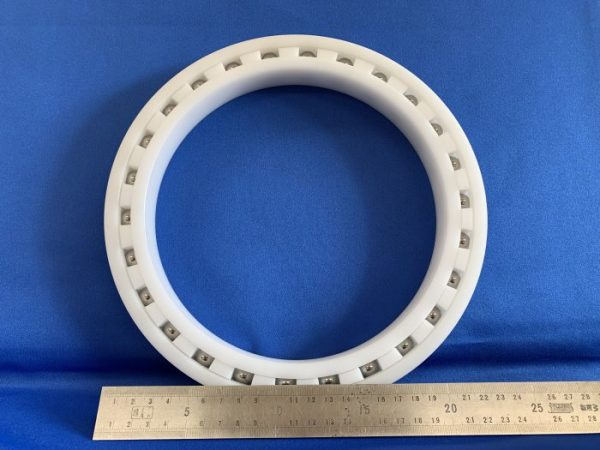

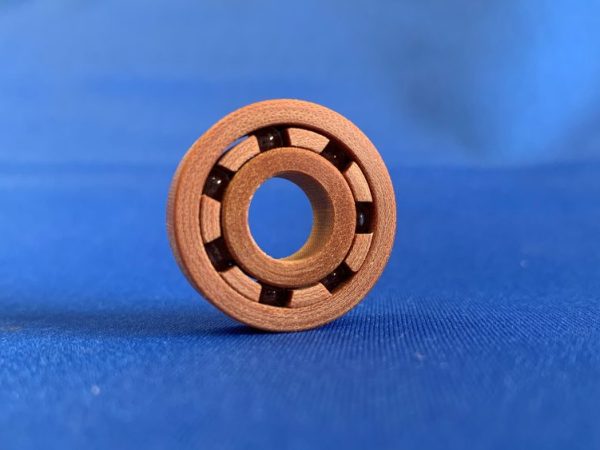

Large Diameter Plastic Ball Bearings (φ200 and above)

This is an example of our large diameter bearing. The photo shows a 6838 bearing (φ240×φ190×24L). This bearing is intended for use in a project involving a generator that utilizes water flow. Given that it will be used underwater, the customer is considering plastic materials and was searching for a manufacturer of large diameter bearings. We provided this bearing in response to their request to try out a few samples for testing purposes. We manufacture bearings through machining, so we can provide bearings in uncommon specifications starting from single units. We have experience in manufacturing and delivering bearings with an outer diameter of φ270 in non-standard dimensions. Additionally, our bearings[…..]