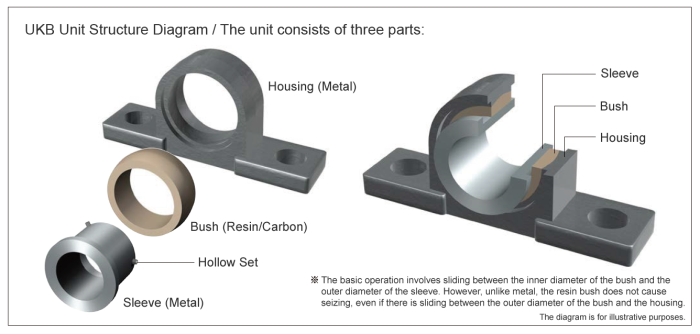

Case Example of Vertical Grooves Processed in Bushings Used for Pillow Blocks

Our pillow blocks come standard as a set of three components: the housing, bushing, and sleeve.

The use of vertical grooves is beneficial for the following purposes: preventing foreign material intrusion, serving as a passage for liquids, and managing wear debris.

[Foreign Material Prevention]

In environments where there is a risk of foreign materials like dust intruding, such materials can enter the sliding parts, leading to rotational failure or reduced lifespan. In such environments, applying vertical grooves can help expel foreign materials, ensuring they do not obstruct rotation.

[Use as a Liquid Passage]

Environments involving liquids such as water are favorable for plastic bearings. This is because the liquid acts as a lubricant and helps dissipate sliding heat, resulting in a longer lifespan compared to dry environments. Similarly, in pillow blocks, the liquid can pass through or remain in these grooves, acting as a lubricant and heat dissipator, thus extending the product’s lifespan.

[Wear Debris Management]

To secure the shaft and sleeve, the outer diameter of the sleeve and the inner diameter of the bushing slide against each other, which can sometimes generate wear debris depending on the conditions. In such cases, the vertical grooves allow the wear debris to escape and accumulate, enabling longer use compared to bushings without grooves.

In addition to vertical grooves, we can also manufacture bushings with spiral grooves.

This case of the spiral grooves serve the same purpose as the liquid passage function mentioned above.

If you are looking to address wear debris or foreign material issues when using pillow blocks, please feel free to contact us.

Similar Case Studies

Pillow Block Usage Examples

- Pillow Block Bearings for Conveyor Rollers in a Sludge Treatment Plant

- Pillow Block Bearings for Cleaning with Sodium Hypochlorite

- Pillow Block for Use in Water Treatment Plants

Related Pages

|

・Pillow Blocks (Bearing Units) |