Today, we would like to talk about PE.

PE, also known as polyethylene, is one of the more inexpensive resins and is used in many applications. For example, the “poly” in “poly tank” comes from polyethylene. Likewise, PE fishing lines are, as the name suggests, made from polyethylene. In this way, PE is used in a wide variety of products, from containers to fishing lines.

Next, let’s look at the characteristics of PE.

Overall Advantages and Disadvantages of PE (Polyethylene)

Advantages

- Low cost

- Excellent chemical resistance

- Extremely low water absorption

- Excellent non-stick properties

- Lightweight

Thanks to its low cost, excellent chemical resistance, and low water absorption, PE is widely used in many plastic products.

Disadvantages

- Low heat resistance (recommended maximum operating temperature for bearings: around 60 °C)

- High coefficient of thermal expansion, so it is more prone to dimensional change

Types of PE (Polyethylene)

While we’ve just listed the general characteristics of PE, it can be broadly divided into two types based on density:

- LDPE (Low-Density Polyethylene) — density: 0.91–0.92

- HDPE (High-Density Polyethylene) — density: 0.92–0.96

There is also a form with an extremely high molecular weight (typically about 1–7 × 106 vs. ~2–3 × 105 for general grades), called UHMWPE (Ultra-High-Molecular-Weight Polyethylene).

Differences in density and molecular weight lead to these classifications, each with distinct characteristics.

Types and Characteristics of PE (Polyethylene)

| LDPE: | Softer than other PEs and sometimes called “soft PE”. Often used in films. |

| HDPE: | Harder than other PEs and sometimes called “hard PE”. Excellent tensile and impact strength; commonly used in extruded products. |

| UHMWPE: | Outstanding impact and wear resistance. Used in many fields, including industrial machinery. Even above its melting point, melt flow is poor, making it unsuitable for injection moulding. Classified as an engineering plastic. |

Examples of Use

| LDPE: | Food packaging film, cushioning material (bubble wrap), plastic bags |

| HDPE: | Plastic tanks, beer crates, plastic buckets |

| UHMWPE: | Fishing lines, industrial products, prosthetics |

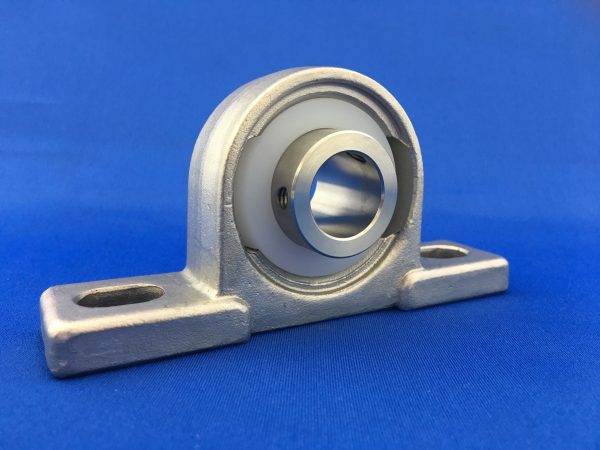

Our bearings use UHMWPE.

Due to its relatively low cost and excellent chemical resistance, UHMWPE is widely used in environments exposed to chemicals or water. It also complies with the Food Sanitation Act, making it suitable for use in food-related equipment.

Examples of UHMWPE Bearing Applications

Examples of actual usage can be found on our Case Studies page.

Pillow unit for sodium hypochlorite cleaning Pillow unit for sodium hypochlorite cleaning |

Resin bearings resistant to phosphoric acid Resin bearings resistant to phosphoric acid |

Bearings for static prevention Bearings for static prevention |

Standard UHMWPE is milky white, but electrically conductive black grades are also available. Since plastics are generally highly insulating and prone to static buildup, conductive UHMWPE is used when static electricity could adversely affect chemicals or products handled in the equipment.

UHMWPE is an excellent material. However, even if dimensions are within tolerance immediately after machining, later measurements may show changes. It also tends to expand in summer and contract in winter. For this reason, we take seasonal dimensional changes into account during machining and adjust our methods to minimise their effects.

Summary

This time we introduced PE, but there are many other materials available. Each has different characteristics, so selecting the right one can be challenging. If you are considering resin bearings or machined resin parts, please feel free to contact us — we can help with material selection and make recommendations.