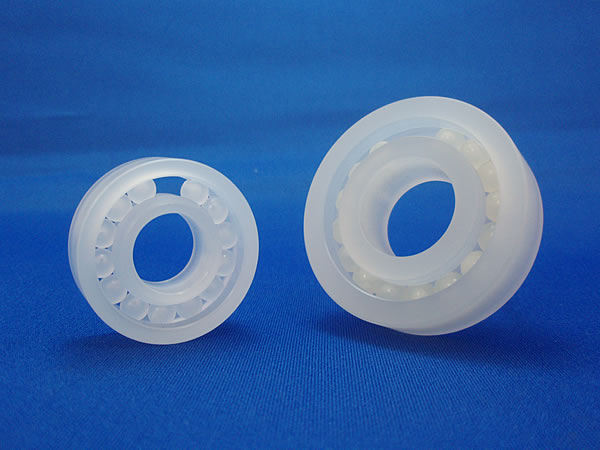

At Kashima Bearings, we specialise in plastic bearings. One challenge we face daily is dimensional change — the way plastics subtly, and sometimes significantly, alter their size.

This article explains why it happens and how we process plastics to maintain the highest precision.

Why Plastics Change Size

There are two main causes:

1. Thermal Expansion

Like most materials, plastics expand when heated and contract when cooled. This principle explains why jar lids can be stuck in summer, why glass cups may crack when filled with boiling water, and why rail tracks require expansion joints.

Some products — such as traditional mercury thermometers — are intentionally designed to take advantage of this property.

2. Water Absorption

Unlike metals, plastics can absorb water — sometimes a significant amount. Certain polymers are engineered for high absorption, as seen in baby diapers or cooling neck scarves. But in engineering components, this property can cause measurable dimensional changes.

The Manufacturing Challenge

For our machining team, dimensional changes — especially in the outer and inner diameters of ball bearings — are a constant consideration.

We never machine components directly to their final dimensions. Instead, we:

- Run small test batches several days in advance

- Measure size changes over time

- Adjust machining parameters accordingly for the production run

Environmental conditions also play a major role:

- Summer: parts tend to expand.

- Winter: parts contract — sometimes even at room temperature. We store them in temperature-controlled chambers at around 25 °C to maintain stability.

- Spring/Autumn: fluctuating conditions make maintaining accuracy especially challenging.

How Big Are the Changes?

Consider one of the most dimensionally unstable plastics we work with:

- A 1000 mm rod at 5 °C can measure 2.7 mm longer at 35 °C.

- With a water absorption rate of 0.8%, that same rod can grow 8 mm after one day immersed in water.

- At maximum (theoretical) saturation, it could expand by 60 mm.

These figures are based on calculations, not extreme in-house tests — but they illustrate why dimensional control is essential.

Our Approach

Working with challenging materials demands constant care. We monitor, store, and process every part to achieve the highest possible precision.

Somewhere, someone needs components with exacting tolerances — and we are ready to deliver them.

Kashima Bearings manufactures high-precision plastic bearings from a wide range of materials. With extensive experience and technical expertise, we can solve even the toughest dimensional challenges. Contact us to discuss your requirements.