Kashima Bearings has been trusted for many years in the Japanese manufacturing industry.

Our strength lies in our deep knowledge of plastic materials and our advanced processing technology, enabling us to customize plastic ball bearings and plastic components to meet the diverse requirements of various factory environments.

Our plastic bearings offer advantages that metal bearings cannot provide — including corrosion resistance, non-magnetic properties, antistatic behavior, lubrication-free operation, electrical insulation, and freedom from rust. These characteristics make Kashima Bearings an excellent choice for a wide range of applications across many industries.

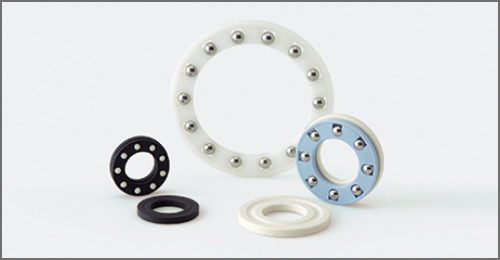

Plastic Ball Bearings

We will offer you the most suitable product for your usage conditions.

Please don't hesitate to contact us if you have any questions.