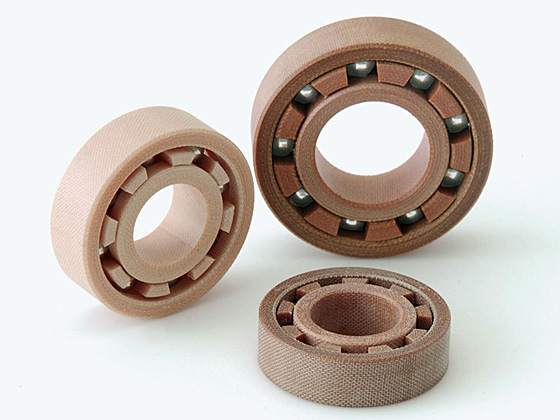

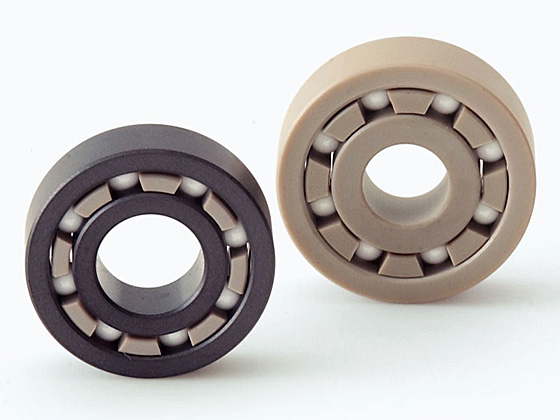

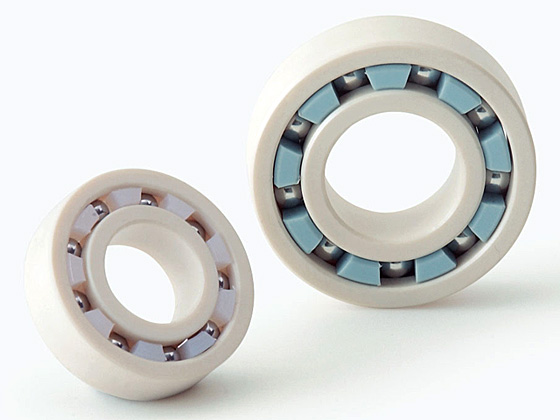

Material selection for outer ring, inner ring, and ball cage

At Kashima Bearings, we manufacture highly functional plastic bearings that utilize a variety of plastic materials not offered by other companies. Based on our previous experience and expertise, we provide suggestions that leverage the properties of plastics.

If you are unsure which plastic material to use, please do not hesitate to contact us.

Phenol |

PTFE PTFE |

UHMW |

PP |

PEEK |

PPS |

PCTFE |

Carbon |

Other Material Other Material |

◎Recommended ○Satisfactory △Possible to use, but not recommended ×Not compatible

| Material | Product Code |

Dry | Water (extended periods of time) |

Water |

Steam | Chemical Environment | Magnetic Environment |

As Insulator |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Acids | Alkaline | Organic Liquids |

Oil | ||||||||

| Phenol | SD | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | ◎ | ◎ |

| SDK | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | × | × | |

| SDHG | ◎ | △ | △ | × | ○ | × | ○ | ◎ | × | × | |

| PTFE | PT | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × |

| PTG | ◎ | ◎ | ◎ | ◎ | ◎ | × | ◎ | ◎ | ◎ | ◎ | |

| PTE | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| PTN | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| UHMW | PE | ○ | ○ | ◎ | × | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PP | PP | △ | ○ | ○ | △ | ○ | ○ | ○ | ○ | ◎ | ◎ |

| PEEK | PK | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PKG | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PPS | PS | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PSG | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PCTFE | PCT | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| PVDF | PV | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| Carbon | CY | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ○ | × |

Note: For details on compatibility with specific chemicals, please feel free to contact us.

Ball Material Selection