|

|

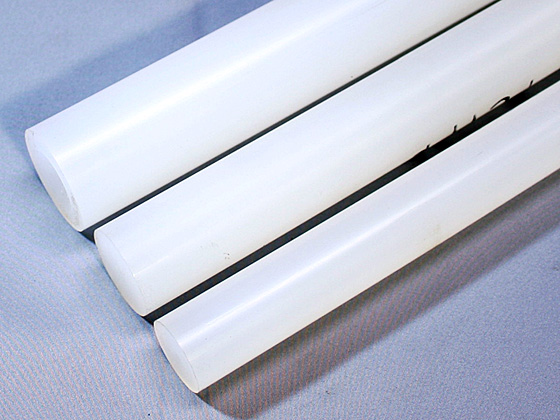

These are the properties of PCTFE (Polychlorotrifluoroethylene), a material used in plastic bearings. Please check the characteristics of this material.

Overview of PCTFE

PCTFE (Poly Chloro Tri Fluoro Ethylene) is a type of fluoropolymer, similar to PTFE, containing fluorine in its molecules. PCTFE exhibits lower heat resistance and chemical resistance compared to PTFE, but it boasts higher mechanical strength and optical properties.

Characteristics of PCTFE

◎Recommended ○Satisfactory △Possible to use, but not recommended ×Not compatible

| Material | Product Code |

Dry | Water (extended periods of time) |

Water |

Steam | Chemical Environment | Magnetic Environment |

As Insulator |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Acids | Alkaline | Organic Liquids |

Oil | ||||||||

| Phenol | SD | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | ◎ | ◎ |

| SDK | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | × | × | |

| SDHG | ◎ | △ | △ | × | ○ | × | ○ | ◎ | × | × | |

| PTFE | PT | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × |

| PTG | ◎ | ◎ | ◎ | ◎ | ◎ | × | ◎ | ◎ | ◎ | ◎ | |

| PTE | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| PTN | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| UHMW | PE | ○ | ○ | ◎ | × | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PP | PP | △ | ○ | ○ | △ | ○ | ○ | ○ | ○ | ◎ | ◎ |

| PEEK | PK | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PKG | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PPS | PS | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PSG | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PCTFE | PCT | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| PVDF | PV | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| Carbon | CY | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ○ | × |

Note: Please contact us for detailed information regarding compatibility with specific chemicals.

Temperature resistance performance of PCTFE

☆Highly recommended ◎Recommended ○Satisfactory △Possible to use, but not recommended ×Not compatible

| Material | Product Code |

Temperature | |||||||

| -190℃~ | -100℃~ | -50℃~ | -20℃~ | Room or Operating Temperature | ~120℃ | ~200℃ | ~350℃ | ||

| Phenol | SD | × | × | 〇 | ◎ | ☆ | ◎ | × | × |

| SDK | × | × | 〇 | ◎ | ☆ | ◎ | × | × | |

| PTFE | PT | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × |

| PTG | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × | |

| PTE | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × | |

| UHMW | PE | × | △ | 〇 | 〇 | ☆ | × | × | × |

| PP | PP | × | △ | 〇 | 〇 | ☆ | 〇 | × | × |

| PEEK | PK | × | × | 〇 | ◎ | ☆ | ◎ | 〇 | × |

| PKG | × | × | 〇 | ◎ | ☆ | ◎ | ◎ | × | |

| PPS | PS | × | × | × | 〇 | ☆ | ◎ | 〇 | × |

| PSG | × | × | × | 〇 | ☆ | ◎ | 〇 | × | |

| PCTFE | PCT | × | × | 〇 | ◎ | ☆ | 〇 | × | × |

| Carbon | CY | × | × | △ | 〇 | ☆ | ◎ | ◎ | ◎* |

*Note: Please consider the coefficient of thermal expansion, or contact us for specialized applications.