|

|

|

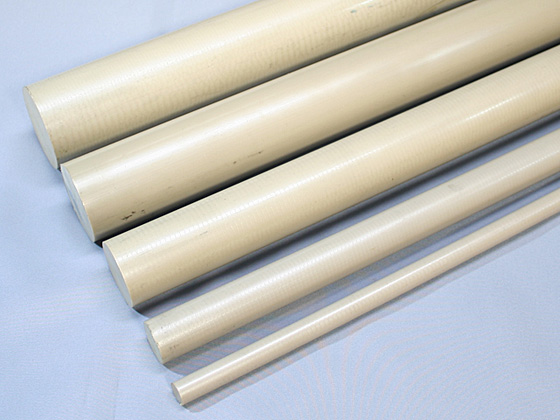

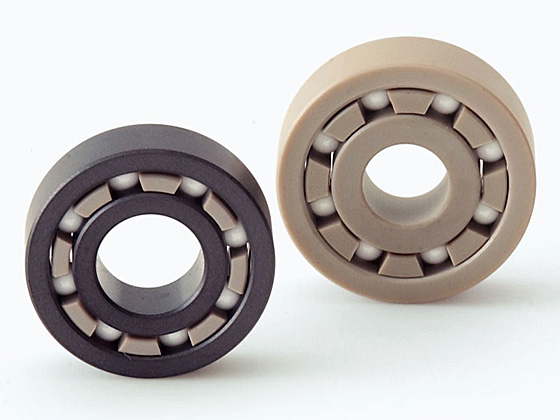

These are the properties of PEEK (Polyetheretherketone), a material used in plastic bearings. Take a look at the characteristics of this material.

Overview of PEEK

PEEK (Polyetheretherketone) is an aromatic polyetherketone resin and belongs to the family of crystalline thermoplastic polymers. It has a basic linear structure with alternating ether and ketone bonds. Polyetherketone (PEK) has an arrangement of ether and ketone bonds in the sequence ether-ether-ketone, while PEEK (Polyetheretherketone) has the bonds arranged in the sequence ether-ether-ketone.

As a thermoplastic polymer, PEEK is distinguished by its exceptionally high heat resistance. It exhibits outstanding resistance to fatigue, abrasion, and chemicals. It also offers good dimensional stability properties. Additionally, it possesses insulation properties and high radiation resistance. PEEK bearings benefit from these attributes, making them suitable for demanding applications. However, PEEK is a very expensive plastic.

Characteristics of PEEK

◎Recommended ○Satisfactory △Possible to use, but not recommended ×Not compatible

| Material | Product Code |

Dry | Water (extended periods of time) |

Water |

Steam | Chemical Environment | Magnetic Environment |

As Insulator |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Acids | Alkaline | Organic Liquids |

Oil | ||||||||

| Phenol | SD | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | ◎ | ◎ |

| SDK | ◎ | ◎ | ◎ | ◎ | ○ | × | ◎ | ◎ | × | × | |

| SDHG | ◎ | △ | △ | × | ○ | × | ○ | ◎ | × | × | |

| PTFE | PT | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × |

| PTG | ◎ | ◎ | ◎ | ◎ | ◎ | × | ◎ | ◎ | ◎ | ◎ | |

| PTE | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| PTN | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| UHMW | PE | ○ | ○ | ◎ | × | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PP | PP | △ | ○ | ○ | △ | ○ | ○ | ○ | ○ | ◎ | ◎ |

| PEEK | PK | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PKG | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PPS | PS | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

| PSG | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | × | |

| PCTFE | PCT | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| PVDF | PV | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| Carbon | CY | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | ○ | × |

Note: Please contact us for detailed information regarding compatibility with specific chemicals.

Temperature resistance performance of PEEK

☆Highly recommended ◎Recommended ○Satisfactory △Possible to use, but not recommended ×Not compatible

| Material | Product Code |

Temperature | |||||||

| -190℃~ | -100℃~ | -50℃~ | -20℃~ | Room or Operating Temperature | ~120℃ | ~200℃ | ~350℃ | ||

| Phenol | SD | × | × | 〇 | ◎ | ☆ | ◎ | × | × |

| SDK | × | × | 〇 | ◎ | ☆ | ◎ | × | × | |

| PTFE | PT | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × |

| PTG | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × | |

| PTE | 〇 | ◎ | ◎ | ◎ | ☆ | ◎ | △ | × | |

| UHMW | PE | × | △ | 〇 | 〇 | ☆ | × | × | × |

| PP | PP | × | △ | 〇 | 〇 | ☆ | 〇 | × | × |

| PEEK | PK | × | × | 〇 | ◎ | ☆ | ◎ | 〇 | × |

| PKG | × | × | 〇 | ◎ | ☆ | ◎ | ◎ | × | |

| PPS | PS | × | × | × | 〇 | ☆ | ◎ | 〇 | × |

| PSG | × | × | × | 〇 | ☆ | ◎ | 〇 | × | |

| PCTFE | PCT | × | × | 〇 | ◎ | ☆ | 〇 | × | × |

| Carbon | CY | × | × | △ | 〇 | ☆ | ◎ | ◎ | ◎* |

*Note: Please consider the coefficient of thermal expansion, or contact us for specialized applications.