Sliding bearings are utilized for the sliding movement between the shaft and the bearing surface. Unlike ball bearings, where the ball makes contact with the groove of the raceway at a single point, plain bearings receive force across a surface, enabling them to withstand higher forces. However, due to the larger contact area, they exhibit a higher coefficient of friction, meaning more force is required to initiate rotation.

Plastic plain bearings offer superior friction and wear characteristics compared to metal plain bearings. Their self-lubricating properties eliminate the need for oil or grease. They can be used maintenance-free even in underwater or chemical environments, or under conditions where grease might be lost due to high temperatures.

Our plain bearings come in various shapes such as liners, blocks, and bushes made of rings. All bearings are machined, allowing customization of dimensions and shapes according to customer requirements. We calculate and propose values necessary for design, including clearances that consider dimensional changes due to water absorption and thermal expansion.

We offer a wide range of materials, enabling us to recommend the most suitable material and shape for the intended environment of the product.

If you have any questions, please don’t hesitate to contact us.

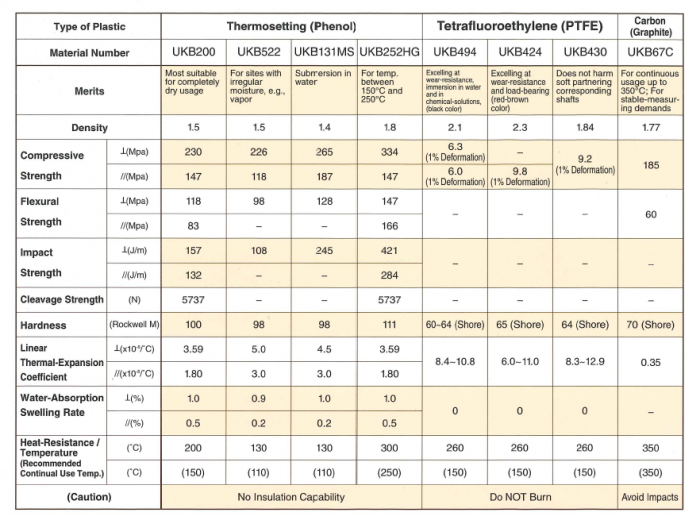

Types and Properties of Plain Bearings

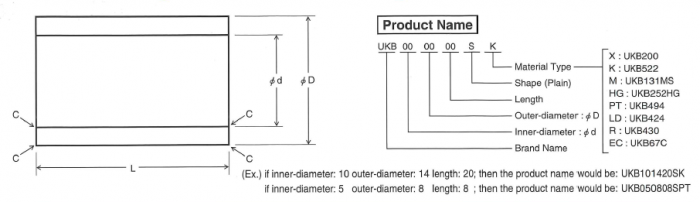

- Standard Diagram of UKB Bushings

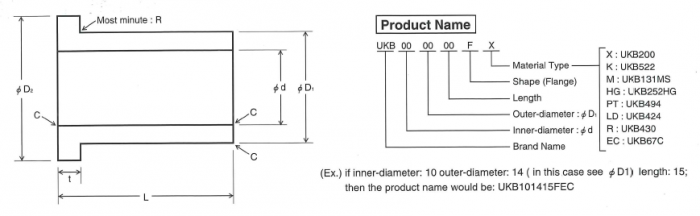

- Standard Design on UKB Bearing with a Flange