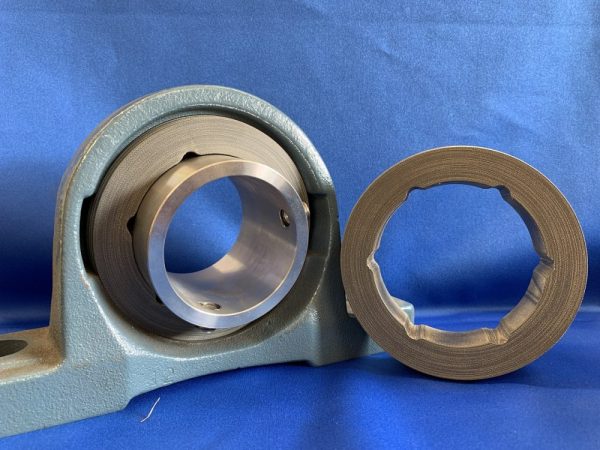

UKB Pillow Block with Vertical Grooved Bushing (Countermeasures for Foreign Particles and Wear Debris in Underwater, Liquid, and Dry Environments)

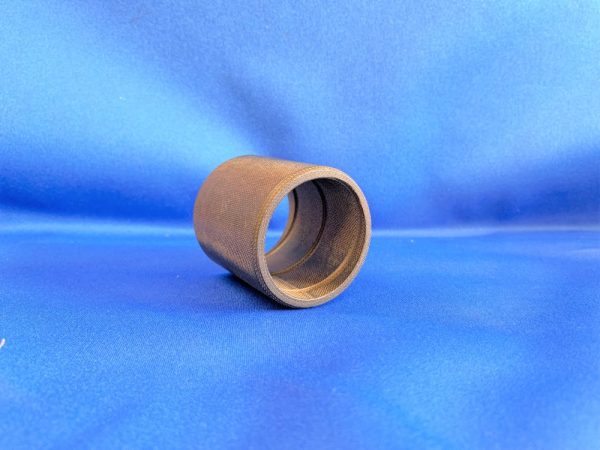

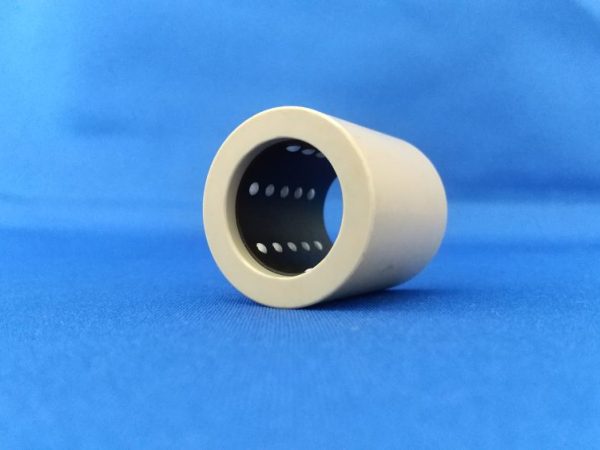

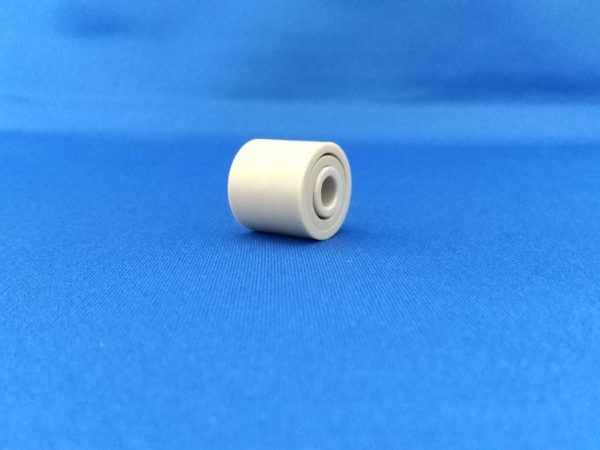

Case Example of Vertical Grooves Processed in Bushings Used for Pillow Blocks Our pillow blocks come standard as a set of three components: the housing, bushing, and sleeve. The use of vertical grooves is beneficial for the following purposes: preventing foreign material intrusion, serving as a passage for liquids, and managing wear debris. [Foreign Material Prevention] In environments where there is a risk of foreign materials like dust intruding, such materials can enter the sliding parts, leading to rotational failure or reduced lifespan. In such environments, applying vertical grooves can help expel foreign materials, ensuring they do not obstruct rotation. [Use as a Liquid Passage] Environments involving liquids such as[…..]